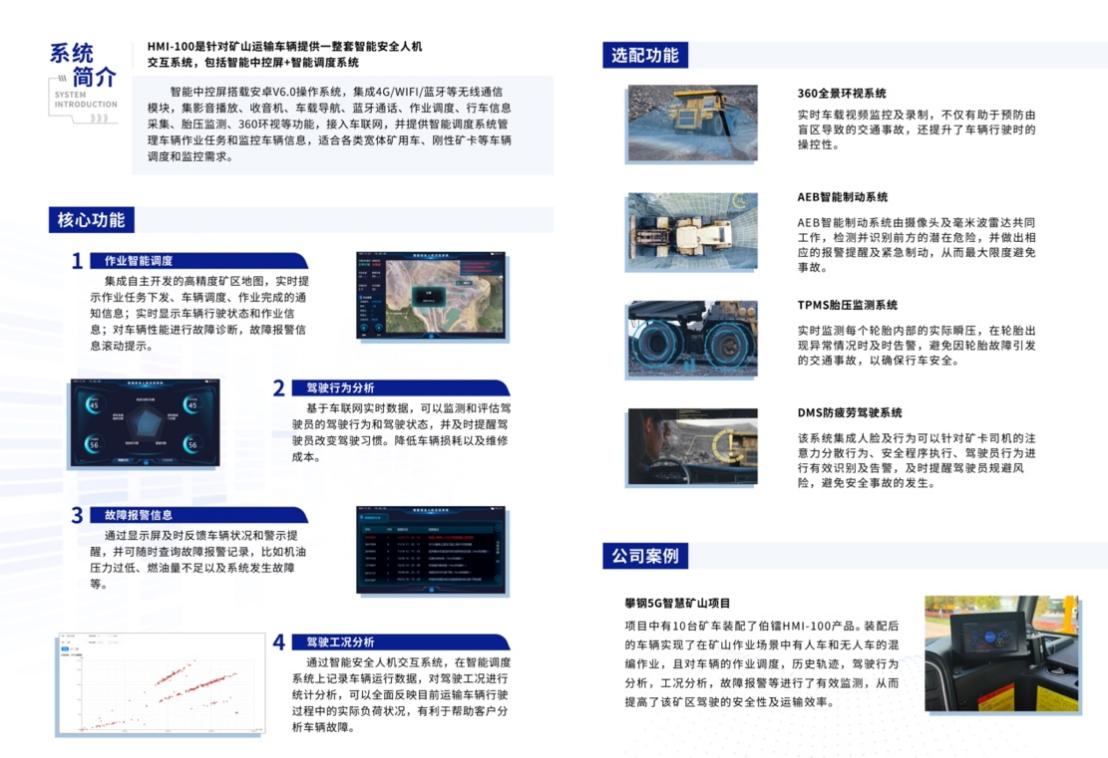

On April 27, Berra technology officially launched the first intelligent and safe human-computer interaction system hmi-100 through an online press conference. National power investment qiyuanxin power, Weichai special vehicle, Xiangdian heavy equipment, Shandong Pengxiang and other major manufacturers and industry experts listened to and witnessed the product release online. This product is independently developed by Berra technology. The intelligent safety human-computer interaction system for mine transportation vehicles is composed of intelligent central control screen and intelligent dispatching system, which can meet the dispatching and monitoring needs of all kinds of wide body mining vehicles and rigid mining cards.

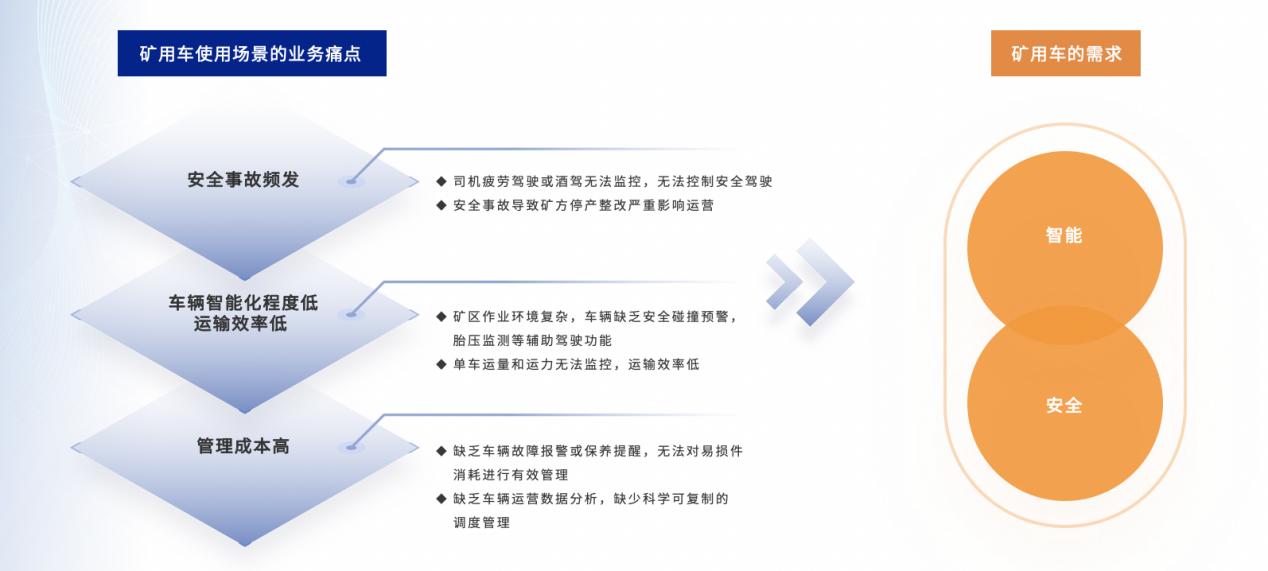

Bola technology has been deeply cultivated in the mining area for many years. It has successively provided automatic driving technical services and automatic driving fleet operation in various mining areas such as Sandaozhuang of Luoyang molybdenum industry, Xigou mine of Jiuquan Iron and Steel Co., Ltd., Zhulan iron mine of Panzhihua Iron and Steel Co., Ltd., Huaneng Huajian coal mine and zhahanur coal mine of Inner Mongolia. It has accumulated rich experience and a large number of road survey data and earthwork transportation volume, and provided first mover advantages such as scene support and data support for product research and development, There is also a clearer sense of the business pain points of the mining vehicle use scenario: the three pain points of frequent safety accidents in the mining area, low vehicle intelligence and high management cost make "intelligence" and "safety" the two core requirements of the current mining vehicle operation. With the popularization of automatic driving technology in mining areas, the mixed operation of manned vehicles and unmanned vehicles has also become a new focus of the industry. The hmi-100 launched by Bola technology this time has the ability to report the location of manned vehicles to the cloud in real time. The unmanned vehicle can seamlessly obtain the location of the surrounding manned vehicles from the same background, effectively solve the problem that the on-board radar can not find the dead corner vehicles in time under large angles and large shielding conditions such as zigzag road and unloading station, and increase the safe driving of unmanned vehicles.

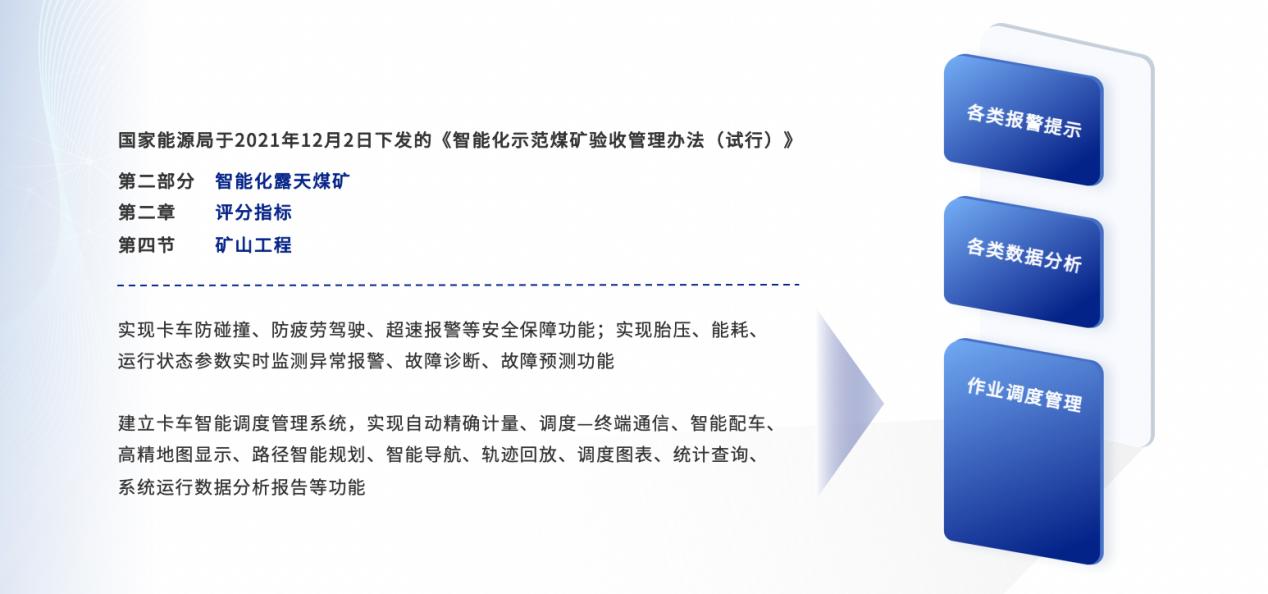

At the press conference, Gu Shengjun, the product manager, introduced that in the face of the overall intelligence of mining vehicles, compared with passenger vehicle monitoring, the corresponding management cost is high. Vehicle alarm, management prompt and operation data mainly depend on the driver, and there is no quantitative and regular management platform; At the same time, the administrative measures for acceptance of intelligent demonstration coal mines (Trial) issued by the National Energy Administration on December 2, 2021 also puts forward clear scoring indicators for intelligent open-pit coal mines, which makes all kinds of alarm prompts, data analysis and operation scheduling management become the rigid needs of mining vehicles.

This product launched by Bora technology takes the Android central control screen as the core at the vehicle end, including three modules: job scheduling, data analysis and fault alarm. Among them, the job scheduling module is the front module, which provides the driver with job information, job statistics and vehicle real-time alarm; The data analysis module provides vehicle historical performance statistics, driving behavior analysis and engine working condition analysis; The fault alarm module provides cloud retrieval of historical faults and standard Chinese definition display. In addition, the vehicle terminal also supports the optional access of 360 look around, tire pressure alarm, anti-collision alarm, anti fatigue alarm and other modules to improve the safety protection ability of the vehicle. The above functions are integrated in the central control screen, with clear functions and low operation threshold. In the cloud, the shovel intelligent dispatching system can establish a high-precision real map of the mining area, set mining and loading, unloading, dumping and other operation areas, and view the historical track of each vehicle; Organize and manage the vehicles in the whole mining area from the cloud and make overall scheduling; Multidimensional analysis of vehicle operation status and fuel consumption, including multi-dimensional analysis of vehicle operation status / driving behavior.

In the Q & a session of the press conference, in view of the concerns of major manufacturers about whether hmi-100 can be compatible with various models, Gu Shengjun answered that at present, the products have been adapted on five mainstream models of main engine manufacturers such as Weichai, Tongli and Beizhong. Although there is no general protocol in the whole market, the user only needs to provide a bus protocol to get through the interface to connect the user's vehicle to the system, Various forms of can data are simplified into standard oil vehicle and tram models and uploaded to the platform to complete subsequent analysis and processing. At the same time, some manufacturers are concerned about how to ensure the stability of hmi-100 in the working scene of high altitude, cold and dust. Gu Shengjun introduced that since January this year, the products have been tested and operated on five ore cars in Jiayuguan Jiugang Xigou mine and Huajian mine in Inner Mongolia, which are more than 4000 meters above sea level. There are no use problems in the process, and the temperature in Xigou mine can be as low as - 20 degrees in winter.

Address:6th Floor, Building 4, No. 388 Shengrong Road, Zhangjiang Science City, Pudong New Area, Shanghai

Telephone:021-58212107

Post code:200124

Mail:info@boonray.com